Natural gas is transported at high pressure; however, it is distributed to industrial users at a lower pressure. Pressure reduction stations are used at these distribution junctions to reduce the gas pressure using a throttling valve. However, a large reduction in pressure will cause a significant drop in the temperature of the gas of approximately 5°C for each 1000kPa reduction in pressure, known as the Joule-Thompson effect.

Pre-heating of natural gas is important to eliminate the Joule–Thomson effect as sub-zero temperatures will often occur if pre-heating is not applied. This can result in embrittlement of pipe and fittings, formation of ice and the formation of hydrates within the pipe with a potential for blockage of filters and regulator/valve seats.

The natural gas is normally heated using an indirect water bath heater (WBH) before the pressure is reduced in order to avoid the formation of ice crystals and hydrates which can cause major damage to equipment. However water bath type heaters result in corrosion problems and water levels have to be maintained constantly requiring high maintenance.

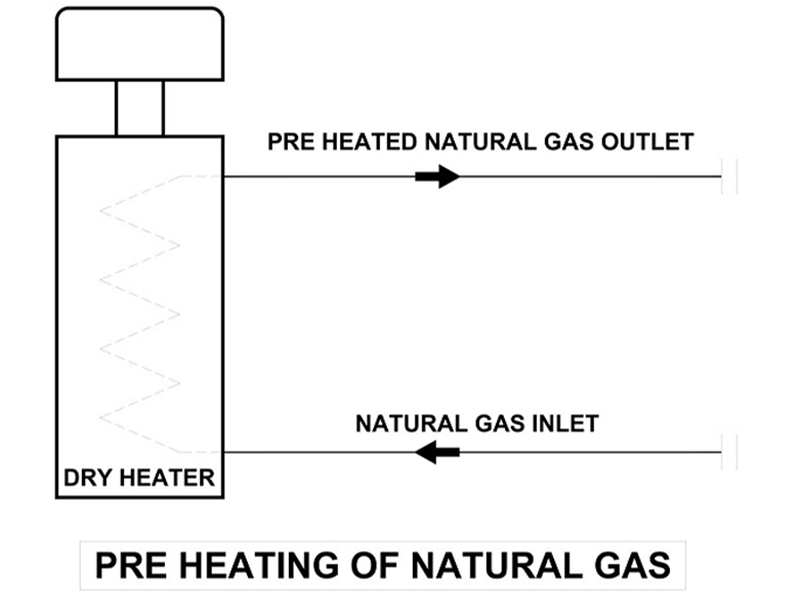

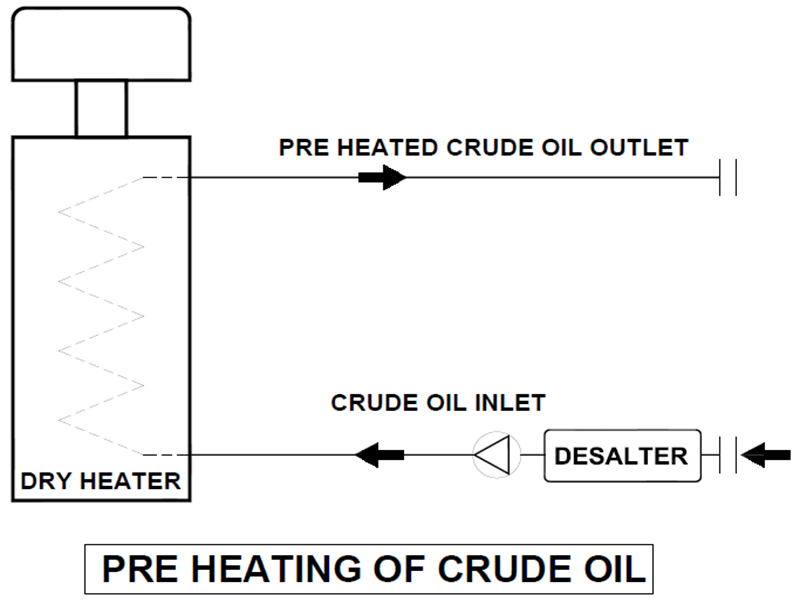

To eliminate these issues the Dry heater can be installed on-line in the natural gas lines where pressure drop is likely to occur to pre-heat the gases upstream to the valves.